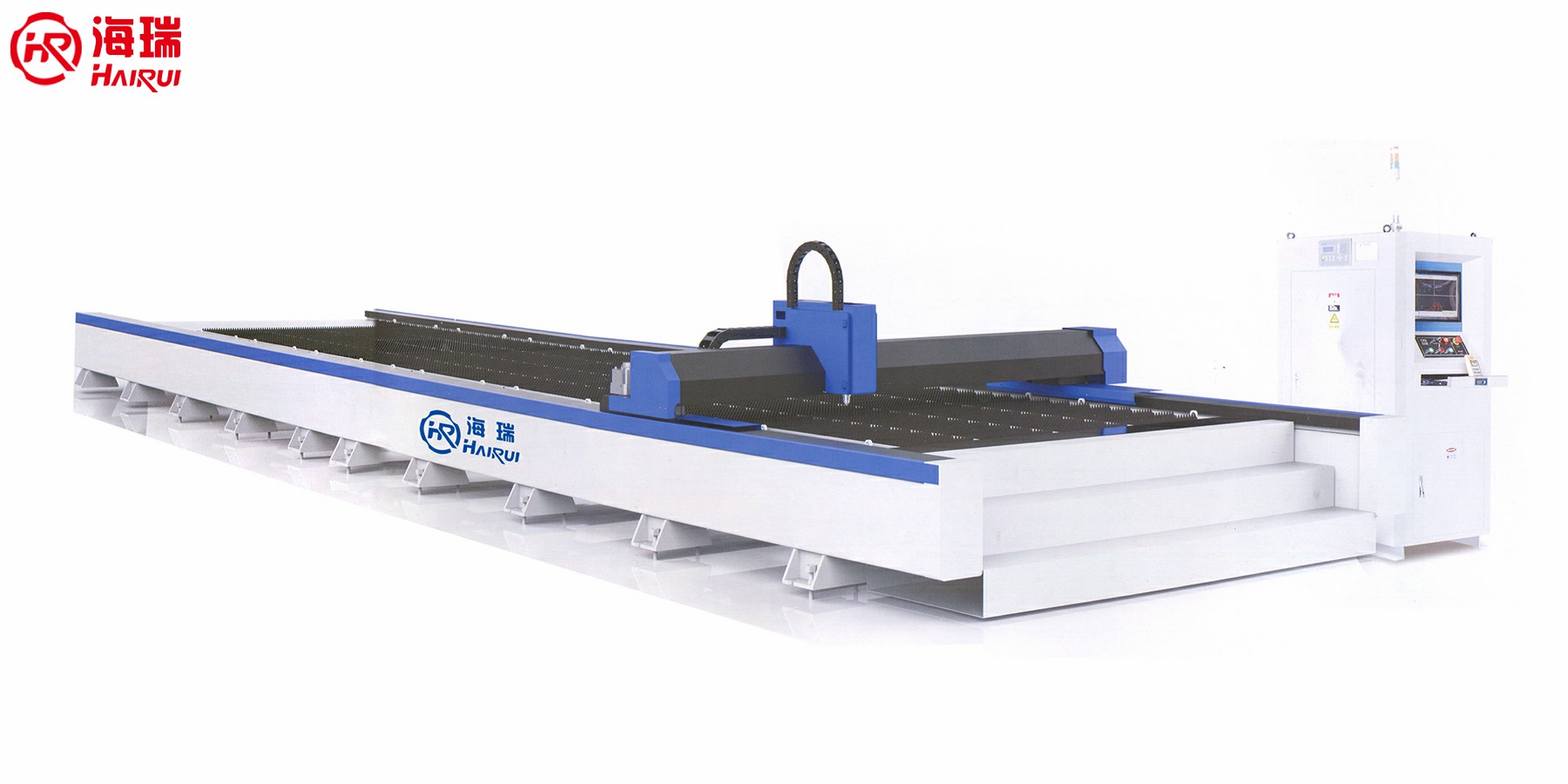

HRLGFC-Large Gantry Fiber Laser Cutting Machine

HRLGFC-large gantry fiber laser cutting machine is fiber laser cutting machine independently developed, designed and manufactured specifically for customers in the metal processing industry to cut large-size medium and thick plate, compared with traditional plasma cutting machine, it has higher cutting precision, and compared with other type fiber laser cutting machine, it has larger cutting range, the equipment has incomparable advantages in the field of high-precision medium and thick plate cutting.

The independently developed, designed and manufactured integral frame machine bed, aviation-grade cast aluminum beam and high-precision drive and transmission components ensure the high precision and high stability of the machine tool, thereby ensuring high cutting accuracy. Its greatest feature is wide width, long stroke, medium and thick plate, the maximum cutting width can reach 5 meters and the maximum cutting length can reach 50 meters, for high-precision cutting of medium and thick plates, it provides a very competitive processing method, which can replace plasma cutting machines with high environmental pollution in most areas, equipped with ventilation system and waste collection trolleys, which improves the working environment and facilitates the cleaning of cutting waste.

Extended Description

The large gantry fiber laser cutting machine has large effective cutting width and length, even comparable to the effective cutting range of the gantry CNC flame & plasma cutting machine. At the same time, with the continuous improvement of laser power, the cutting ability of large gantry fiber laser cutting machines is getting stronger and stronger. In 2020, 12000W-15000W fiber lasers are mainly used for medium and thick plate cutting, in 2021, 15000W-20000W fiber lasers are mainly used for medium and thick plate cutting, in 2022, 20000W-30000W fiber lasers are mainly used for medium and thick plate cutting, in 2023, the power of fiber laser for medium and thick plate cutting has reached 40000W, which is bringing leap-forward change to the metal plate processing industry. Compared with plasma cutting medium and thick plates, laser cutting has obvious advantages such as high cutting precision, fast cutting speed, small kerf, high precision cutting holes, low cutting cost and so on, large gantry fiber laser cutting machines are widely used in industries such as steel structures, pressure vessels, locomotives and ships, bridges, power generation equipment and so on.

The equipment is expensive and the market demand is far less than other types of fiber laser cutting machines, so it will not be prepared in advance, and it will be made now after signing the contract, generally, it will take 45-60 days for the production cycle.

Technical Parameters

|

HRLGFC-Large Gantry Fiber Laser Cutting Machine |

Number |

Item |

Detail |

|

01 |

Effective Cutting Width |

3000-5000mm |

|

|

02 |

Effective Cutting Length |

12000-50000mm |

|

|

03 |

X Axis Effective Distance |

3100-5100mm |

|

|

04 |

X Axis Quickly Positioning Speed |

80m/min |

|

|

05 |

Y1/Y2 Axis Effective Distance |

12100-50100mm |

|

|

06 |

Y1/Y2 Axis Quickly Positioning Speed |

80m/min |

|

|

07 |

Z Axis Effective Distance |

180mm |

|

|

08 |

Z Axis Quickly Positioning Speed |

30m/min |

|

|

09 |

X Axis Positioning Accuracy |

±0.03mm |

|

|

10 |

X Axis Repeated Positioning Accuracy |

0.02mm |

|

|

11 |

Y1/Y2 Axis Positioning Accuracy |

±0.03mm |

|

|

12 |

Y1/Y2 Axis Repeated Positioning Accuracy |

0.02mm |

|

|

13 |

Z Axis Positioning Accuracy |

±0.01mm |

|

|

14 |

Z Axis Repeated Positioning Accuracy |

0.005mm |

|

|

15 |

Fiber Laser Power |

12000-40000W |

|

|

16 |

IP Grade |

IP54 |

|

|

17 |

Input Power Supply |

3×380/400/415V, 50/60Hz |

|

|

18 |

Equipment Main Color |

RAL 5015 Himmelblau or Customized |