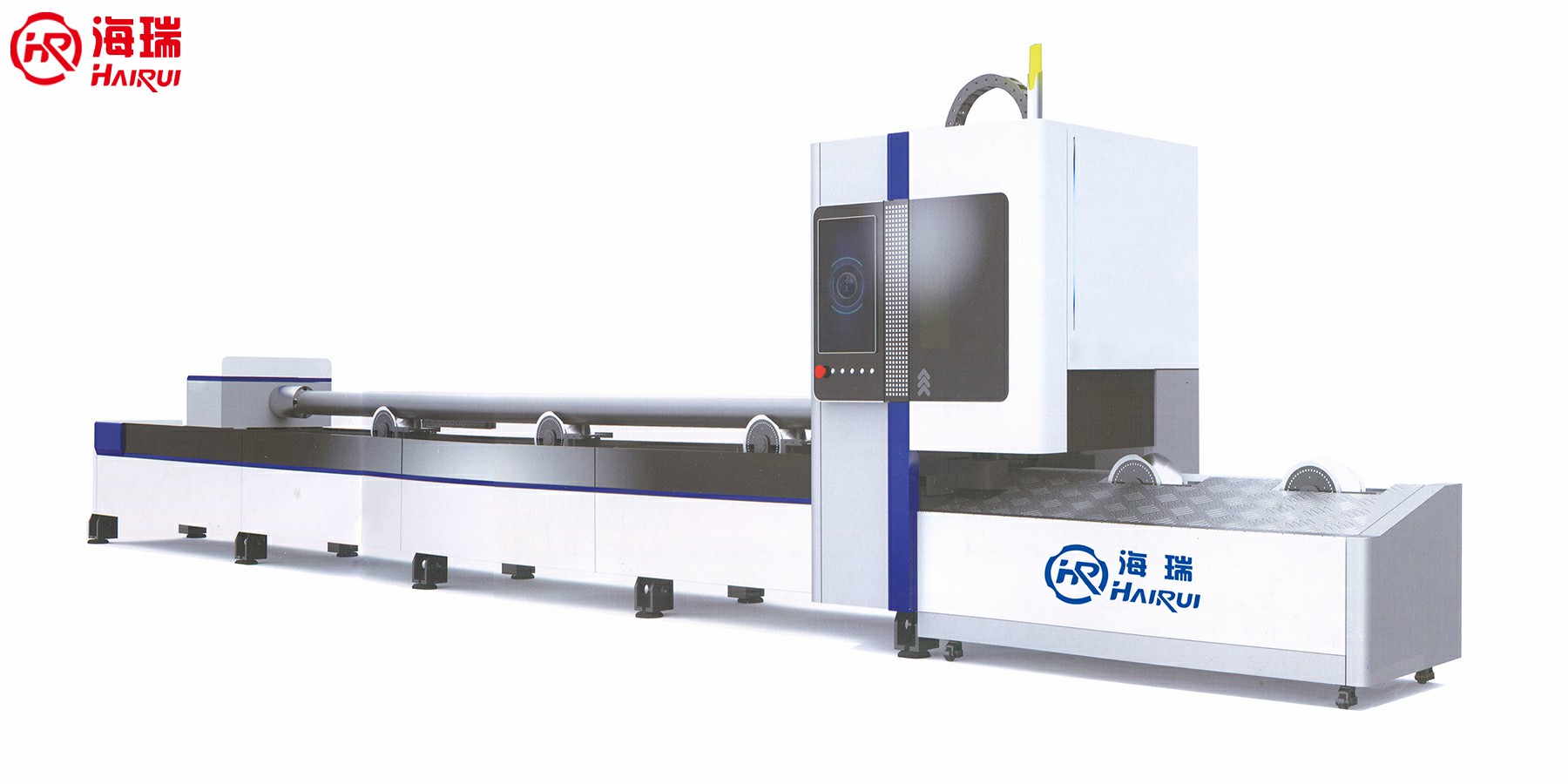

HRPFC-Fiber Laser Cutting Machine For Pipe

HRPFC-fiber laser cutting machine for pipe is fiber laser cutting machine independently developed, designed and manufactured for customers with pipe cutting needs, compared with the traditional CNC pipe flame & plasma cutting machine, the cutting accuracy and cutting efficiency are higher, and it is ideal equipment in the field of precision pipe cutting.

The independently developed, designed and manufactured integral frame machine bed, high-precision self-centering pneumatic chuck and high-precision drive and transmission components ensure the high precision and high stability of the machine tool, thereby ensuring high cutting accuracy, equipped with ventilation system and waste collection trolleys, which improves the working environment and facilitates the cleaning of cutting waste. The standard configuration is the double chuck and double drive, and three chuck and three drive are optional to further improve the cutting accuracy, push type pipe cutting method makes the remaining tail material shorter.

Extended Description

The fiber laser cutting machine for pipe is mainly used to cut round pipes and square pipes, compared with the traditional CNC pipe flame & plasma cutting machine, the fiber laser cutting machine for pipe has higher cutting precision and faster cutting speed. Although the size of the pipe that can be cut is larger than before with the increase of the size of the pneumatic chuck, the size of the pipe that can be cut is still small, far less than the size of the pipe that can be cut by the CNC pipe flame & plasma cutting machine. Considering that the size of the pipe to be cut is small and the wall thickness is thin, low power laser is generally selected for pipe cutting. The standard double chuck and double drive structure can meet the high precision cutting requirements of most pipes, if there is higher precision cutting requirement, three chuck and three drive structure can be optional.

There are four models of this equipment for choose, the best-selling model is the 6000-R220-S150 model. However, the overall market demand for this equipment is not large, so there is generally no inventory. Production begins after signing the contract, and the production cycle is about 20-30 days.

Technical Parameters

|

HRPFC-Fiber Laser Cutting Machine For Pipe |

Number |

Item |

Detail |

|

01 |

Round Pipe Diameter Range |

20-220/20-325mm |

|

|

02 |

Square Pipe Side Length Range |

20-150/20-230mm |

|

|

03 |

Effective Cutting Length |

6000/12000mm |

|

|

04 |

X Axis Effective Distance |

180mm |

|

|

05 |

X Axis Quickly Positioning Speed |

120m/min |

|

|

06 |

Y1/Y2 Axis Effective Distance |

6050/12050mm |

|

|

07 |

Y1/Y2 Axis Quickly Positioning Speed |

120m/min |

|

|

08 |

Z Axis Effective Distance |

150mm |

|

|

09 |

Z Axis Quickly Positioning Speed |

30m/min |

|

|

10 |

W1/W2/W3 Axis Effective Distance |

360° Infinite Rotation |

|

|

11 |

W1/W2/W3 Axis Quickly Positioning Speed |

120rpm |

|

|

12 |

X Axis Positioning Accuracy |

±0.03mm |

|

|

13 |

X Axis Repeated Positioning Accuracy |

0.02mm |

|

|

14 |

Y1/Y2 Axis Positioning Accuracy |

±0.03mm |

|

|

15 |

Y1/Y2 Axis Repeated Positioning Accuracy |

0.02mm |

|

|

16 |

Z Axis Positioning Accuracy |

±0.01mm |

|

|

17 |

Z Axis Repeated Positioning Accuracy |

0.005mm |

|

|

18 |

W1/W2/W3 Axis Positioning Accuracy |

±0.03° |

|

|

19 |

W1/W2/W3 Axis Repeated Positioning Accuracy |

0.02° |

|

|

20 |

Fiber Laser Power |

1000-12000W |

|

|

21 |

IP Grade |

IP54 |

|

|

22 |

Input Power Supply |

3×380/400/415V, 50/60Hz |

|

|

23 |

Equipment Main Color |

RAL 5015 Himmelblau or Customized |