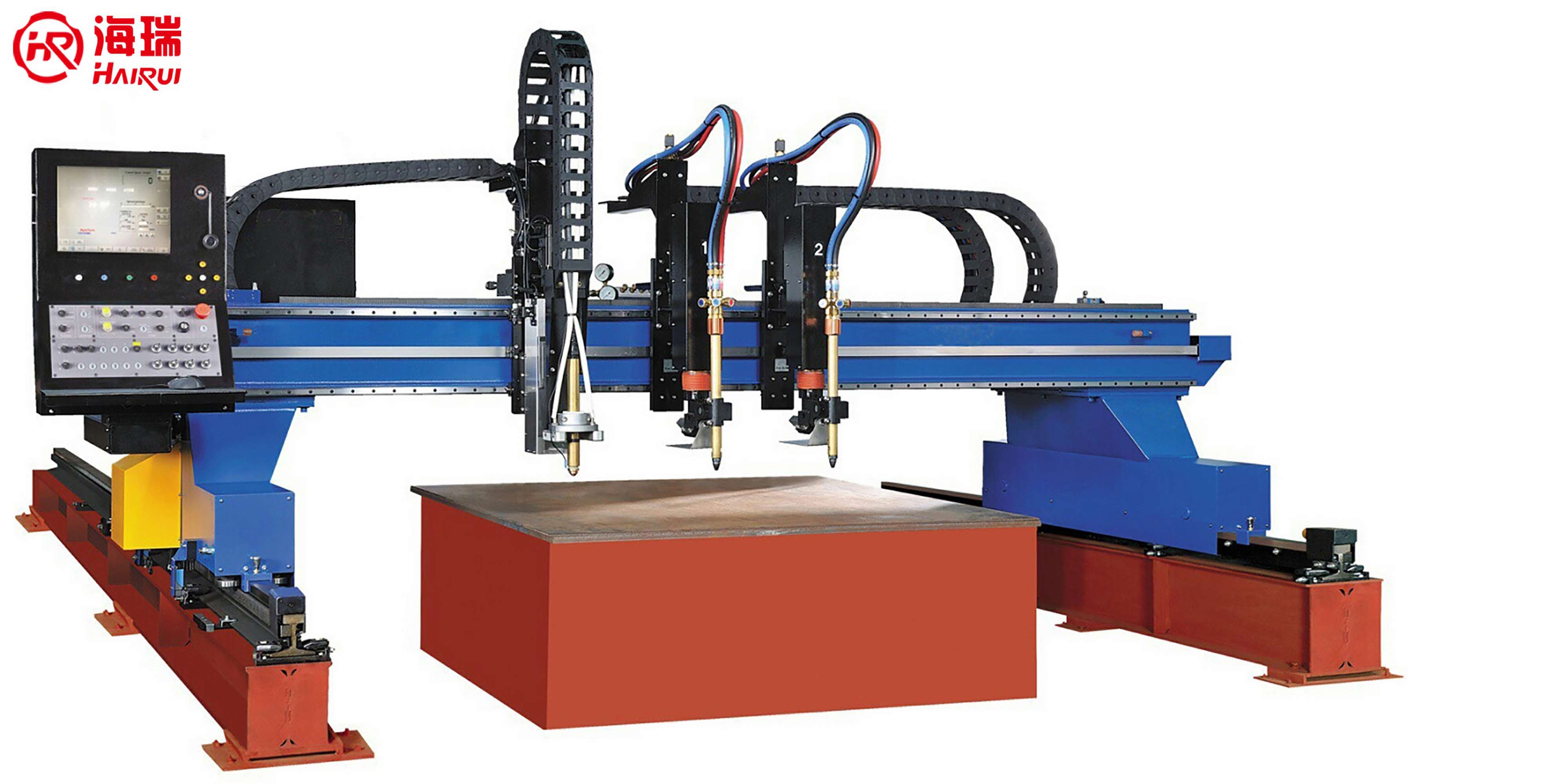

HRGC-Gantry CNC Flame & Plasma Cutting Machine

HRGC-gantry CNC flame & plasma cutting machine is controlled by the CNC system, with the movement of the machine tool, the flame cutting torch & plasma cutting torch installed on the machine tool will cut the plate. Flame cutting and plasma cutting have their own characteristics, flame cutting torch has the ability to cut thick plates, but it can only cut carbon steel, plasma cutting torch can cut all metal materials, but the cutting ability is not as good as flame cutting torch.

The equipment adopts guide rail, machine tool and worktable split structure, when the equipment is installed, the machine tool is directly placed on the guide rail, the eccentric guide wheel is installed next to the traveling wheel of the end frame of the machine tool, which is used to clamp the guide rail to guide the longitudinal movement of the machine tool in straight line. By adjusting the clamping degree of the eccentric guide wheel and the guide rail, the longitudinal movement of the machine tool is stable and reliable. The standard worktable (made by the customer) is an ordinary worktable, and an optional ventilation system is used to absorb the dust generated by cutting to improve the working environment. It is a high-precision and high-efficiency automatic cutting equipment.

Compared with the traditional portable type and cantilever type, it has obvious advantages such as larger cutting range, better equipment operation stability, higher cutting precision, higher cutting efficiency and so on.

The maximum guide rail center distance of this equipment can reach 12 meters, and the guide rail length can reach tens of meters or even hundreds of meters, and it can be equipped with up to 12 sets of CNC cutting torch moving devices. It can be equipped with 12 sets of CNC flame cutting torches and 12 sets of CNC plasma cutting torches, the 12 sets of CNC flame cutting torches can cut at the same time or the 12 sets of CNC plasma cutting torches can cut at the same time. The cutting efficiency is quite high, much higher than various other types of sheet metal cutting machines. The cutting efficiency of this equipment is quite high, which is much higher than that of various other types of metal sheet cutting machines. At the same time, the equipment can optional equipped with straight flame cutting torch to meet the needs of steel structure manufacturers for cutting strips in batches.

From flame cutting to plasma cutting, and then from plasma cutting to laser cutting, and as the fiber laser cutting technology becomes more and more mature and the laser power is getting bigger and bigger, the laser cutting ability is getting stronger and stronger, so more and more metal sheet cutting needs are gradually being replaced by fiber laser cutting machine. Not only the demand for flame and plasma cutting torches to cut special-shaped plates is gradually replaced by fiber laser cutting machine, but even the demand for batch cutting strips with straight flame cutting torches is gradually being replaced by fiber laser cutting machine.

Extended Description

The gantry CNC flame & plasma cutting machine adopts split structure of guide rail, machine tool and worktable, compared with the desktop type, the configuration is more flexible, in actual use, the length of the guide rail can be increased to increase the effective cutting length. However, after long-term use, due to the influence of many factors, the cutting accuracy is slightly worse than that of the desktop type. The maximum guide rail center distance of this equipment can reach 12 meters, and the guide rail length can reach tens of meters or even hundreds of meters. Multiple steel plates can be placed on the worktable at the same time, which is especially suitable for mass cutting of large workpieces.

The equipment with guide rail center distance of 3-6 meters are the best-selling models, and there are always stocks and semi-finished products. If the required configuration is different from the stocks, semi-finished products can be used for assembly and debugging according to different configurations at any time, and the delivery time is 2-3 days. The other models are made now according to the orders, and the delivery time is 10-20 days.

Technical Parameters

Economical Series

|

HRGC(E)-Gantry CNC Flame & Plasma Cutting Machine-Economical Series |

Number |

Item |

Detail |

|

01 |

Guide Rail Center Distance |

2000-3000mm |

|

|

02 |

Effective Cutting Width |

Guide Rail Center Distance-500mm |

|

|

03 |

Guide Rail Length |

4000-10000mm |

|

|

04 |

Effective Cutting Length |

Guide Rail Length-1000mm |

|

|

05 |

Quickly Positioning Speed |

3000mm/min |

|

|

06 |

CNC Cutting Torch Moving Device |

Max.2 |

|

|

07 |

Longitudinal Drive Mode |

Stepper (Optional Servo) Bilateral Drive |

|

|

08 |

IP Grade |

IP54 |

|

|

09 |

Input Power Supply |

3×380/400/415V, 50/60Hz |

|

|

10 |

Equipment Main Color |

RAL 5015 Himmelblau or Customized |

Standard Series

|

HRGC(S)-Gantry CNC Flame & Plasma Cutting Machine-Standard Series |

Number |

Item |

Detail |

|

01 |

Guide Rail Center Distance |

3000-12000mm |

|

|

02 |

Effective Cutting Width |

Guide Rail Center Distance-800mm |

|

|

03 |

Guide Rail Length |

Customized |

|

|

04 |

Effective Cutting Length |

Guide Rail Length-2000mm |

|

|

05 |

Quickly Positioning Speed |

6000mm/min |

|

|

06 |

CNC Cutting Torch Moving Device |

Max.12 |

|

|

07 |

Longitudinal Drive Mode |

Servo Bilateral Drive |

|

|

08 |

IP Grade |

IP54 |

|

|

09 |

Input Power Supply |

3×380/400/415V, 50/60Hz |

|

|

10 |

Equipment Main Color |

RAL 5015 Himmelblau or Customized |

Fine Small Hole Series

|

HRGC(F)-Gantry CNC Flame & Plasma Cutting Machine-Fine Small Hole Series |

Number |

Item |

Detail |

|

01 |

Guide Rail Center Distance |

3000-6000mm |

|

|

02 |

Effective Cutting Width |

Guide Rail Center Distance-800mm |

|

|

03 |

Guide Rail Length |

Customized |

|

|

04 |

Effective Cutting Length |

Guide Rail Length-2000mm |

|

|

05 |

Quickly Positioning Speed |

12000mm/min |

|

|

06 |

CNC Cutting Torch Moving Device |

Max.4 |

|

|

07 |

Longitudinal Drive Mode |

Servo Bilateral Drive |

|

|

08 |

IP Grade |

IP54 |

|

|

09 |

Input Power Supply |

3×380/400/415V, 50/60Hz |

|

|

10 |

Equipment Main Color |

RAL 5015 Himmelblau or Customized |

Pipe & Plate Integrated Series

Pipe Cutting Function Description

|

two-axis linkage |

four-axis linkage |

six-axis linkage |

|

non-groove cutting: round pipe |

groove cutting: round pipe non-groove cutting: square pipe/channel steel/angle steel/H-shaped steel |

groove cutting: round pipe/square pipe/channel steel/angle steel/H-shaped steel |

|

|

|

|